PRODUCTS

Hot Products

Products cover: different specifications of horizontal mixers, vertical mixers, fully automatic cookie production lines, baking tunnel ovens and various non-standard customized baking food machinery.

ABOUT US

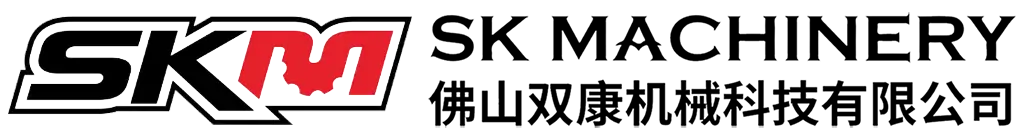

Foshan SK Machinery Technology Co., Ltd.

The founder of SK has accumulated years of experience in food machinery production. Adhering to the philosophy of 'survival through quality and development through reputation,' we insist on using craftsmanship to create conscientious products and provide comprehensive services to our customers—from plant layout planning and design, equipment production, manufacturing and installation and commissioning, operator technical training, food production formulas, and later technical upgrades.

Horizontal Mixer

Vertical Mixer

Cookie Mixer

Horizontal Bread Mixer

Tunnel Oven

Tough Cookie Production Line

Shortbread Cookie Production Line

Cookie Production Line

Solutions

The SK automated cookie and shortbread production line uses automated equipment configuration, using an automatic feeding machine and a cookie and biscuit extrusion and cutting machine, which can produce two-color cookies and Farleys biscuits. It is equipped with a tunnel oven or rotary oven, an unloading cooling conveyor line, a chocolate bottom pouring machine, a cooling tunnel oven, and a cooling chocolate slurry and conveyor line. After conveying, the biscuits are stacked, and then manually placed into trays and enter the packaging machine's entire production process.

Diversified Solutions

Partners

Qualification and Patent Certification

News

Different specifications of horizontal mixers, vertical mixers, fully automatic cookie production lines, baking tunnel ovens, and various non-standard customized baking food machinery.

The cookie production line, from feeding to three-roll sheeting, shaping, sugar screening, conveying, and waste recovery, cooperates with a tunnel oven for baking, and oil spraying and cooling are all completed automatically by mechatronics integration. The thickness of the biscuits can be adjusted freely, and the mechanical rotation speed can be adjusted steplessly from fast to slow. It also has a series of advanced equipment such as fully automatic temperature control.

The cookie production line, from feeding to three-roll sheeting, shaping, sugar screening, conveying, and waste recovery, cooperates with a tunnel oven for baking, and oil spraying and cooling are all completed automatically by mechatronics integration. The thickness of the biscuits can be adjusted freely, and the mechanical rotation speed can be adjusted steplessly from fast to slow. It also has a series of advanced equipment such as fully automatic temperature control.

Gulf Food Manufacturing Company (Dubai)

The cookie production line, from feeding to three-roll sheeting, shaping, sugar screening, conveying, and waste recovery, cooperates with a tunnel oven for baking, and oil spraying and cooling are all completed automatically by mechatronics integration. The thickness of the biscuits can be adjusted freely, and the mechanical rotation speed can be adjusted steplessly from fast to slow. It also has a series of advanced equipment such as fully automatic temperature control.

Do you have any questions?

If you have any questions about our products, please leave your information, and we will contact you within 24 hours.